Mabaka a ho phunyeha ha hlobo ea mehele a batla a rarahane 'me a lokela ho hlahlojoa ka ho qaqileng;leha ho le joalo, li ka akaretsoa ka mabaka a latelang:

1. E bakoa ke thepa ea ring die le boleng bo se nang letho

1)Thepa e sebelisoang ka har'a lesale ke le leng la mabaka a bohlokoa.Hajoale, selikalikoe sa China se shoa haholo ho sebelisoa 4Cr13 le 20CrMnTid, tse batlang li tsitsitse.Leha ho le joalo, ho na le bahlahisi ba fapaneng ba thepa.Bakeng sa boitsebiso bo tšoanang, ho tla ba le liphapang tse itseng linthong tsa trace, tse tla ama boleng ba hlobo ea lesale.

2)mokhoa oa ho qapa.Ena ke sehokelo sa bohlokoa ts'ebetsong ea tlhahiso ea hlobo.Bakeng sa liforomo tsa tšepe tse phahameng tsa alloy, hangata ho na le litlhoko tsa sebopeho sa metallographic joalo ka kabo ea carbide ka thepa.Thempereichara ea mocheso le eona e lokela ho laoloa ka thata, ho lokisoe lintlha tse nepahetseng tsa ho futhumatsa, ho amoheloe mekhoa e nepahetseng ea ho fereka, 'me ho lokela ho etsoa ho pholisa butle kapa ka nako e nepahetseng ka mor'a ho fereka.Mekhoa e sa tloaelehang e ka lebisa habonolo mapetsong a setopo sa lesale.

3)Ho itokisetsa ho phekola mocheso.Ho itšetlehile ka thepa le litlhoko tsa hlobo, mekhoa ea ho lokisa mocheso e kang annealing le quenching le tempering e sebelisoa ho ntlafatsa sebopeho, ho felisa mefokolo ea moralo ho forging le likheo, le ho ntlafatsa ts'ebetso.Kalafo e nepahetseng ea ho lokisetsa mocheso oa tšepe e phahameng ea carbon alloy hlobo e ka felisa li-carbides tsa marang-rang, li-spheroidize le ho hloekisa li-carbide, le ho khothalletsa kabo ea carbide e tšoanang.Sena se tla thusa ho netefatsa boleng ba quenching le tempering le ho eketsa bophelo ba hlobo.

2. Ring shoa kalafo mocheso

1)ho tima le ho kokobetsa.Ena ke sehokelo sa bohlokoa kalafong ea mocheso oa hlobo.Haeba ho futhumala ho feteletseng ho etsahala nakong ea ho tima le ho futhumatsa, ho ke ke ha baka feela brittleness e kholoanyane ea workpiece, empa hape ho baka deformation le ho phunyeha habonolo nakong ea pholileng, e amang bophelo ba hlobo ka ho teba.Litlhaloso tsa ts'ebetso ea mocheso li lokela ho laoloa ka thata 'me phekolo ea mocheso oa vacuum e lokela ho sebelisoa.Ho futhumatsa ho lokela ho etsoa ka nako ka mor'a ho tima, 'me mekhoa e fapaneng ea mocheso e lokela ho amoheloa ho latela litlhoko tsa tekheniki..

2)khatello ea maikutlo annealing.Hlobo e lokela ho ba tlas'a khatello ea khatello ea maikutlo annealing ka mor'a ho sebetsa ka thata ho felisa khatello ea kelello e ka hare e bakoang ke ho sebetsa ka thata ho qoba ho senyeha ho feteletseng kapa mapetsong a bakoang ke ho tima.Bakeng sa liforomo tse nang le litlhoko tse phahameng tse nepahetseng, phekolo ea ho fokotsa khatello ea kelello e hlokahalang ka mor'a ho sila, e leng molemo ho tsitsisa ho nepahala ha hlobo le ho eketsa bophelo ba eona ba tšebeletso.

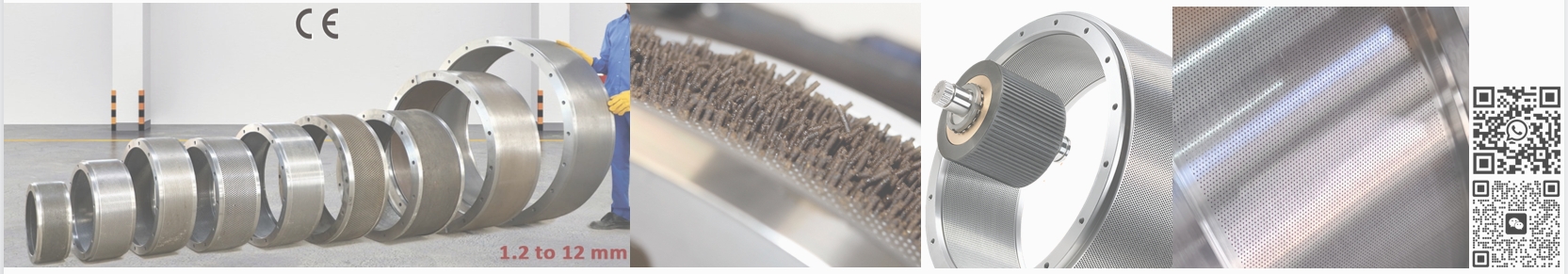

3. Karolelano ea ho bula ea hlobo ea lesale

1)Haeba sekhahla sa ho bula lesale se le holimo haholo, monyetla oa ho phatloha ha ring e tla eketseha.Moetsi e mong le e mong oa hlobo o tla ba le phapang e batlang e le kholo ka lebaka la maemo a fapaneng a kalafo ea mocheso le lits'ebetso.Ka kakaretso, lihlahisoa tsa k'hamphani ea rona li ka eketsa sekhahla sa ho bula ka 2-6% motheong oa hlobo ea mofuta oa pele, 'me e ka netefatsa bophelo ba ts'ebeletso ea hlobo ea lesale.

4. Ho roala lesale

1)Ha lesale la lesale le apesoa ka botenya bo itseng 'me matla a fokotsehile hoo a ke keng a mamella khatello ea granulation, ho phatloha ho tla etsahala.Ho kgothaletswa hore ring die die e nkelwe sebaka ka nako ha lesale la difaele le apeswa ho fihlela moo di-grooves tsa kgatello di phallang teng.

5. Tšebeliso ea lesale die

1)Nakong ea ts'ebetso ea granulation ea lesale la shoa, palo ea lintho tse kenang e ke ke ea lumelloa ho sebetsa ka 100% mojaro ka lebaka la tlhahiso e phahameng ea granulation ea lesale e shoa ka boeona.Ts'ebetso e joalo ea nako e telele le e matla haholo e tla boela e lebise ho phunyeha ha lesale..Re khothaletsa ho laola mojaro ho 75-85% ho netefatsa hore bophelo ba ts'ebeletso ea lesale boa shoa.

2)Haeba selikalikoe se senyehile 'me rolara ea khatello li hatelloa ka thata haholo, ho phatloha ho ka etsahala habonolo.Ka kakaretso, re hloka hore sebaka se pakeng tsa selikalikoe le "rolara ea khatello" se laoloe pakeng tsa 0.1-0.4mm.

6. Mefuta e mengata

1) Ho phunyeha ho ka etsahala ha lintho tse thata tse kang li-blocks tsa tšepe li hlaha ka har'a thepa ea granulated.

7. Ho kengoa ha lifensetere le litaba tsa granulator

1) Lesale la lesale ha le kenngoe ka thata mme ho na le lekhalo pakeng tsa lona le granulator.Ring e ka 'na ea phatloha nakong ea granulation.

2) Kamora kalafo ea mocheso, hlobo ea lesale e tla holofala haholo.Haeba e sa lokisoe, hlobo ea selikalikoe e tla phatloha nakong ea tšebeliso.

3) Ha granulator ka boeona e na le phoso, joalo ka shaft e ka sehloohong ea granulator e sisinyehang, joalo-joalo.

Information Support Contact Information:

Whatsapp: +8618912316448

E-mail:hongyangringdie@outlook.com

Nako ea poso: Jan-25-2024