1. Ha ho fihla nako ea ho se be le lithibela-mafu, lintho tse thibelang mocheso tse kang li-probiotics li kenngoa butle-butle lijong tsa pellet. Ka lebaka leo, nakong ea ts'ebetso ea tlhahiso ea lijo, mocheso le oona o tla ba le tšusumetso ea bohlokoa haholo boleng ba lijo tsa pellet. Haeba mocheso o phahame haholo nakong ea tlhahiso ea phepelo ea pellet, e tla bolaea lintho tse sa utloeleng mocheso joalo ka li-probiotics. Haeba mocheso o le tlase haholo, lintho tsa baktheria tse ka har'a phepelo ea pellet li ke ke tsa hloekisoa ka ho feletseng, e leng se hlahisang tlhahiso ea lijo tsa pellet. Boleng ha bo lekane. Ka hona, e le ho qoba tšusumetso ea mocheso tekong, tlhahlobo ena ke ho ithuta tšusumetso ea mocheso oa mocheso le "die hole aspect ratio" ho boleng ba ts'ebetso ea phepelo ea pellet tlas'a maemo a tlase a mocheso, e le ho ithuta tlhahiso ea li-pellets tsa phepelo ea pellet tlas'a maemo a lumellanang ka mor'a hore lisebelisoa tse tala li butsoitse. Hore na e tletse le hore na e lumellana le litekanyetso tsa tlhahlobo ea boleng ba likaroloana. Sepheo se seholo sa teko ena ke ho fana ka tataiso e itseng ea khopolo-taba bakeng sa tlhahiso ea lijo tsa pellet ea liphoofolo.

2.1 Lisebelisoa tse ka sehloohong tsa lijo tsa liteko le lihlahisoa tse tala tsa pellet li kenyelletsa: poone, lijo tsa tlhapi, letsoai, methionine, threonine, joalo-joalo Poone e hloka ho siloa ka likaroloana tse ntle tsa 11.0mm, ebe lihlahisoa tse tala li aroloa ho ea ka litlhoko tsa phepo e nepahetseng, ebe li hōla. Ka mor'a ho pholile, lintho tse sa utloisiseng mocheso tse kang li-probiotics li kenngoa, 'me qetellong li halefa ka likaroloana. Lithempereichara tsa li-pellets tsa phepelo ea maemo hangata ke 60, 50, 40, le 30 ° C, 'me bolelele le bophara ba masoba hangata ke 7: 1, 6: 2, 10: 1, le 300 mg / kg ea lintho tsa probiotic li eketsoa ho latela lisebelisoa tsa tlhahlobo. , 'me mocheso oa phepelo ea pellet o boetse o hloka ho halefa ho sireletsa mosebetsi oa li-probiotics. Ho feta moo, divithamine tse ding di tlameha ho ekeletswa kilogramo e nngwe le e nngwe ya phepelo ya pellet ho netefatsa hore dielemente tsa phepo tsa phepelo ya pellet di ka fihlella ditlhoko tsa phepo ya naha.

2.2 Ho etsa lisampole le ho bokella lisampole

E le ho etsa bonnete ba hore phepelo ea pellet e hlahisoang e loketse, ka mor'a hore phepelo ea pellet e hlahisoe, hoa hlokahala ho khetha ka mokhoa o sa reroang phepelo ea pellet bakeng sa tlhahlobo ea boleng.

2.3 Maemo le mekhoa ea tlhahlobo ea boleng

2.3.1 Tekanyo ea gelatinization ea starch

Ha ho hlahlojoa tekanyo ea gelatinization ea starch ka lisampole tsa phepelo ea pellet, basebetsi ba ka sebelisa amylase ho e lemoha. Kenya amylase ho starch, 'me u bale karabelo ea lik'hemik'hale lipakeng tsa amylase le starch. Qetellong, eketsa tharollo ea iodine, 'me u ahlole tekanyo ea starch gelatinization ka ho shebella botebo ba' mala oa phello ea lik'hemik'hale.

2.3.2 Ho thatafala ha li-pellets tsa phepelo

E le ho hlahloba boleng ba phepelo ea pellet, ho thatafala ha eona ho boetse ho hloka ho lekoa. Tekanyetso ea boima ba phepelo ea pellet e lokela ho lebisa tlhahisoleseling e nepahetseng.

2.3.3 Lenane la ho mamella lijo tsa pellet

Kenya phepelo ea pellet ka lebokoseng la rotary 'me u e fetole ka 50r / min bakeng sa metsotso e 20. Kamora ho emisa, ntša phepelo ea pellet ebe u lekanya boima bo setseng ba phepelo ea pellet ebe u bo hlahisa ka m.

3. liphetho tsa liteko

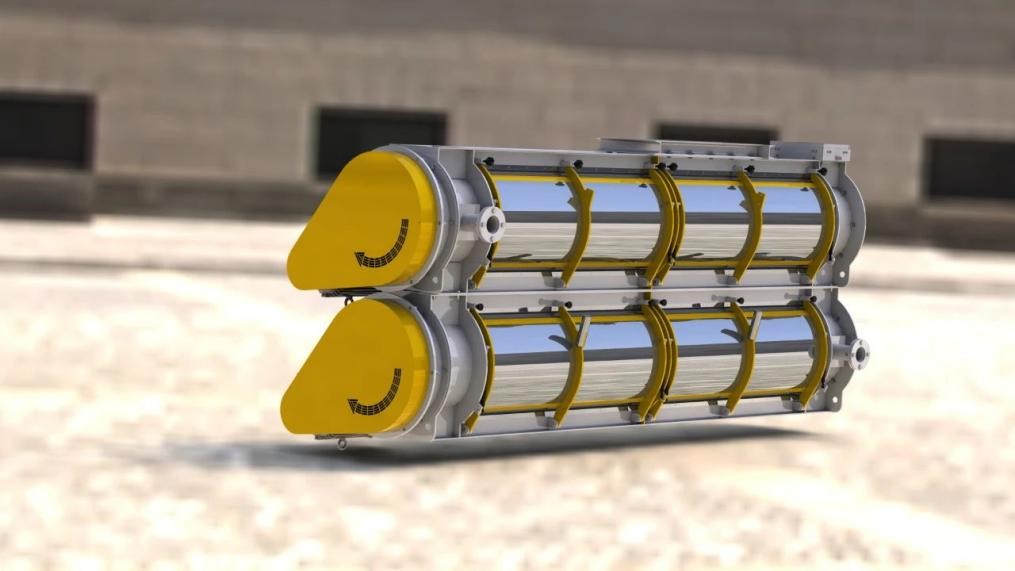

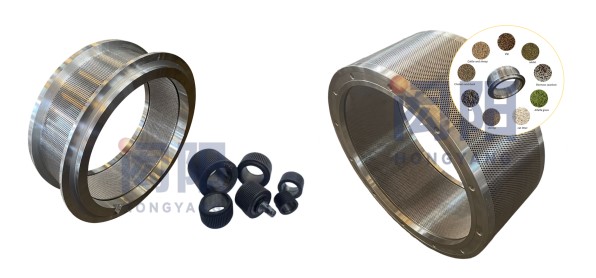

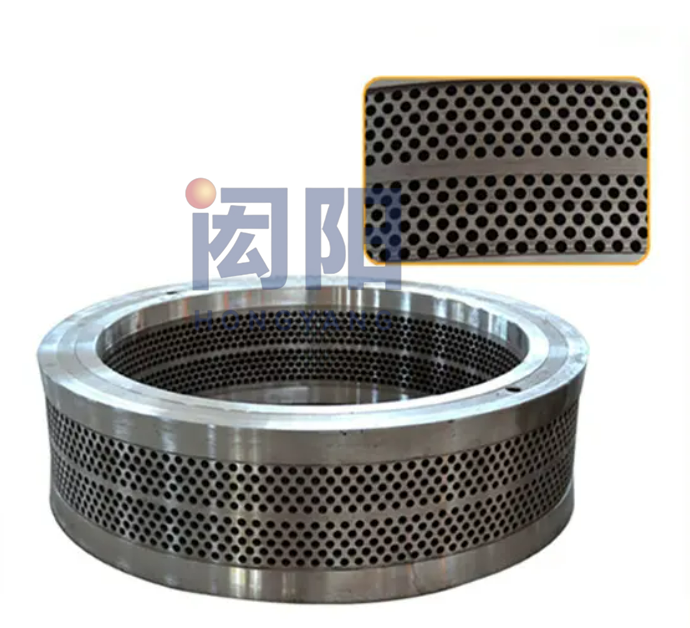

3.1 Tšusumetso ea boleng ba phepelo, mocheso le karo-karolelano ea sekoti boleng le boima ba phepelo ea pellet. Teko ena e ithuta haholo ka phetoho ea boleng ba phepelo ea pellet tlasa maemo a mocheso a tlase. Lisebelisoa tse tala li kenyelletsa poone, lijo tsa soya, joalo-joalo, tse sebetsoang le ho holisoa. Ka mor'a moo, e granulated ka mocheso o tlase. Ho ile ha fumanoa hore boleng ba phepelo ea pellet ha bo ame feela ka karolo ea lihlahisoa tse tala, empa hape le bophara ba lesoba la lefu la mochine o sebetsang. Ha mocheso oa ho hlahisa phepelo ea pellet o phahame, karo-karolelano ho bophara le bolelele ba lesoba la lera la mochine e kholoanyane, 'me boima ba phepelo ea pellet e hlahisoang bo phahame, empa bo tla ama ts'ebetso ea li-probiotics ho fepa,' me matla a sebelisoang ho hlahisa phepelo ea pellet e tla boela e eketsehe. Liphetho tsa liteko li bonts'a hore ho netefatsa hore boleng ba phepelo ea pellet e hlahisoang bo fihla maemong, bo hloka ho hlahisoa tlasa maemo a joalo a tlhahiso.

3.2 Tšusumetso ea mocheso oa boemo le bophara ba lesoba ho tekanyo ea gelatinization ea starch ka phepelong ea pellet. Ka mor'a letoto la liphuputso tsa liteko, ho ile ha fumanoa hore mocheso oa boemo ba mochine le bophara ba lesoba la die ho na le tšusumetso ea bohlokoa haholo ho tekanyo ea starch gelatinization ea phepelo ea pellet. Ka tlas'a maemo a tšoanang a mocheso, ha bophara ba lesoba le lenyenyane, ho ba le tšusumetso e kholo ho tekanyo ea gelatinization ea starch phepelong ea pellet.

3.3 Tšusumetso ea mocheso oa mocheso le bophara ba lesoba ho isa bolelele ba tekanyo ea ho boloka li-probiotics ka har'a granules. Ka mor'a letoto la liteko, ho ile ha fumanoa hore mosebetsi oa li-probiotics o ameha haholo ke mocheso. Haeba mocheso o phahame haholo nakong ea tlhahiso ea phepelo ea pellet, e tla fokotsa ka ho toba mosebetsi oa li-probiotics. Ka hona, e le ho etsa bonnete ba ho boloka li-probiotics nakong ea tlhahiso ea lijo tsa pellet le litekanyetso tsa tlhahlobo ea boleng ba phepelo ea pellet, hoa hlokahala ho hlahisa lijo tsa pellet tlas'a maemo a tlaase a mocheso.

4. Qetello

Ka teko ena, ho ka fumanoa hore boleng, boima le palo ea li-probiotics lijong tsa pellet ha li amehe feela ke mocheso oa tlhahiso, empa hape le bophara ba lesoba la die. Ka letoto la liphuputso, ho ile ha fumanoa hore ho sebelisa lisebelisoa tse tala tse hōlileng bakeng sa tlhahiso ea phepelo ea pellet tlas'a maemo a tlaase a mocheso ho thusa ho ntlafatsa boleng le boima ba phepelo ea pellet; tlas'a maemo a tšoanang a mocheso, ho phahama ha karo-karolelano ea bophara ba lesoba, ho hlahisa li-pellets tse ntle. Matla a sebelisoang ts'ebetsong ea ho fepa a phahame. Ka liteko, ho ile ha fumanoa hore tharollo e nepahetseng ea ho hlahisa phepelo ea pellet ke ho sebelisa thepa e nang le tekanyo ea bophara ba lesoba la 6:1 mocheso oa 65 ° C ho hlahisa phepelo ea pellet ea boleng bo phahameng ka ho fetisisa.

Nako ea poso: Jan-10-2024