IDAH Ring Die Die Pellet Machine Parts

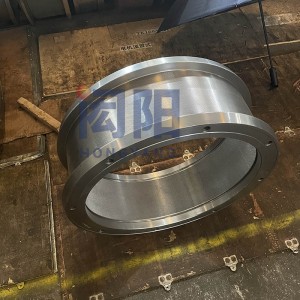

IDAH Ring Die

1. Khetha thepa ea boleng bo holimo, ho etsa litšepe tsa bobeli, le li-billet tsa tšepe tse defoaming;

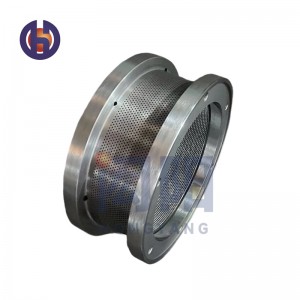

2. Thepa ea lesale: X46Cr13 (tšepe e sa hloekang)

3. Ho phunya lithunya tse tsoang linaheng tse ngata tse tsoang linaheng tse ling, ho bopa ka nako e le 'ngoe, boleng bo phahameng, tekanyo e tlaase ea ho phunya likoti, le tekanyo e phahameng ea ho ntša metsi;

4. Motsoako oa sebōpi sa vacuum le sebōpi se sa khaotseng sa ho tima ho ntlafatsa bophelo ba tšebeletso;

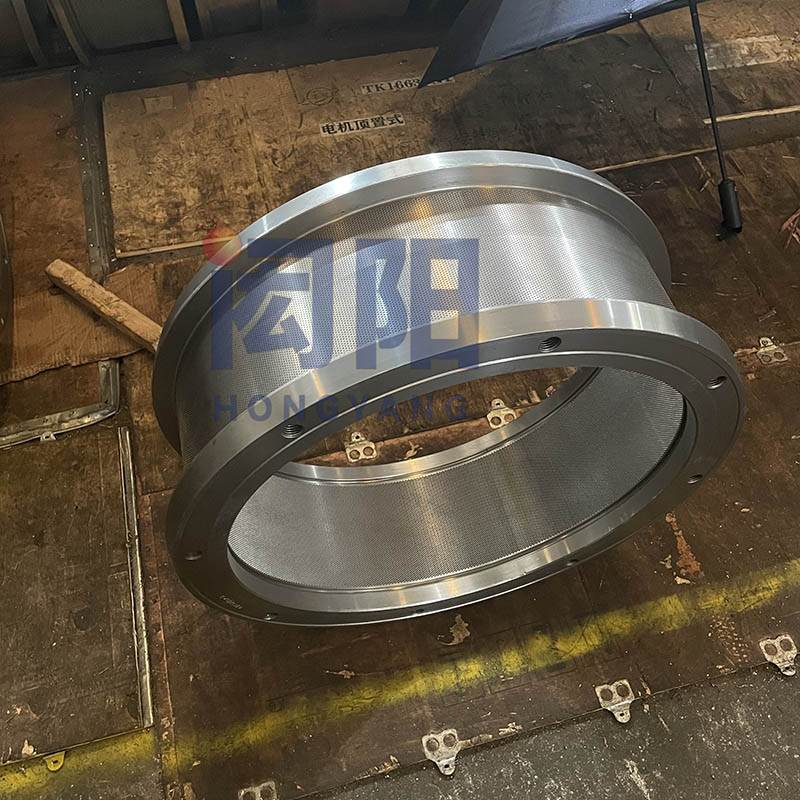

5. Iketsetse karo-karolelano ea khatello le matla ho latela lisebelisoa le litlhoko tsa moreki;

6. Etsa ka tieo tlhahlobo ea boleng nakong ea ts'ebetso eohle ea tlhahiso ho netefatsa boleng ba sehlahisoa.

| S/N | Mohlala | SizeOD * ID * bophara ka kakaretso * bophara ba pad -mm | Boholo ba lesoba mm |

| 1 | IDAH530 | 680*530*258*172 | 1-12 |

| 2 | IDAH530F | 680*530*278*172 | 1-12 |

| 3 | IDAH635D | 790*635*294*194 | 1-12 |

Compression ratio

Tekanyo ea khatello ea selikalikoe ke efe?

The compression karo-karolelano ea lesale die ke karo-karolelano ea sebetsang hantle bolelele ba lesale lesoba le bophara ba lesoba die. Ke index e bonts'ang matla a extrusion a phepelo ea pellet. E kholoanyane karo-karolelano ea compression ke, matla a li-pellets tse extruded li matla, empa tlhahiso e tla ba tlase haholo. E nyenyane karo-karolelano ea compression, holim'a sefahleho sa pellet e tla ba thata 'me sebopeho se sebe se tla ba teng, empa sehlahisoa se tla ba se phahameng.

U ka khetha tekanyo e nepahetseng ea compression joang?

Ka lebaka la libopeho tse fapaneng, lisebelisoa tse tala, le mekhoa ea granulation, khetho ea tekanyo e nepahetseng ea compression e itšetlehile ka boemo. Tse latelang ke mefuta e akaretsang e ipapisitseng le boiphihlelo:

Lijo tsa liphoofolo le likhoho: 1:8 ho ea ho 13; Lijo tsa litlhapi: 1:11 ho ea ho 16;

Lijo tsa li-shrimp: 1:16 ho isa ho 25; Lijo tse thibelang mocheso: 1: 7 ho isa ho 9; Lijo tsa furu le joang: 1: 5 ho isa ho 7.

Ka mor'a ho sebelisa ring die, mohlahisi oa phepelo a ka boela a fetola karo-karolelano ea aperture le compression ea selikalikoe se latelang ho latela maikutlo a kantle a fepa.

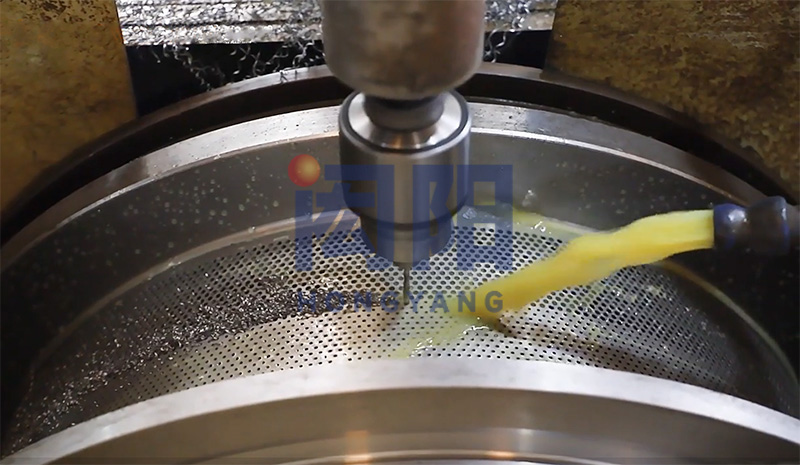

Theknoloji ea ho sebetsa

Theknoloji ea ho lokisa li-ring die: Ho seha → Ho qhekella → Ho hloeka → Ho tloaeleha → Ho tloaeleha → Ho phethela → Ho tima le ho futhumatsa → Ho phethela → Lesoba la ho cheka → Ho Nitriding→ Ho polishing → Teko ea khatello → Ho hanyetsa → Oli e rusitseng → Lekola 'me u boloke likhetho