Hammer Blade Crusher Blade For Hammer Mill

Tlhahisoleseding ya Sehlahiswa

Lehare la hamore le sebelisoa hangata lits'ebetsong tsa ho sila le ho sila indastering. Li-blade tsena li etselitsoe ho ama le ho pshatla lisebelisoa tse fapaneng, ho kenyelletsa lijo-thollo, liminerale le lisebelisoa tse ling.

Ho na le mefuta e fapaneng ea mahare a hamore, a ipapisitseng le sebopeho sa ona, boholo le sebopeho sa ona, joalo ka lihamore tsa tungsten carbide, lihamore tse boreleli le lihamore tsa 'moba. Mofuta oa lehare la hamore o sebelisoang o itšetlehile ka mofuta oa thepa e sebelisoang le sephetho se lakatsehang.

Lisebelisoa tsa lehare la hamore li kenyelletsa: tšepe e tlaase ea carbon, tšepe e bohareng ea carbon, tšepe e khethehileng ea tšepe, joalo-joalo.

Boholo le sebopeho sa lehare la hamore li ka etsoa ka mokhoa o ikhethileng ho lumellana le lits'ebetso le lisebelisoa tse fapaneng, ho lumella ho sila kapa ho sila ho lebisitsoeng le ho sebetsa hantle.

Lehare la hamore ke karolo e sebetsang ea crusher e otlang thepa ka ho toba, kahoo ke karolo e apereng e nang le ho apara ka potlako le ho nkeloa sebaka khafetsa. Ha li-angles tse 'nè tse sebetsang tsa hamore li apere, li lokela ho nkeloa sebaka ka nako.

Likarolo tsa Sehlahisoa

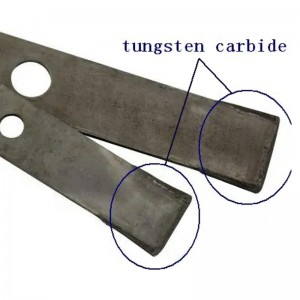

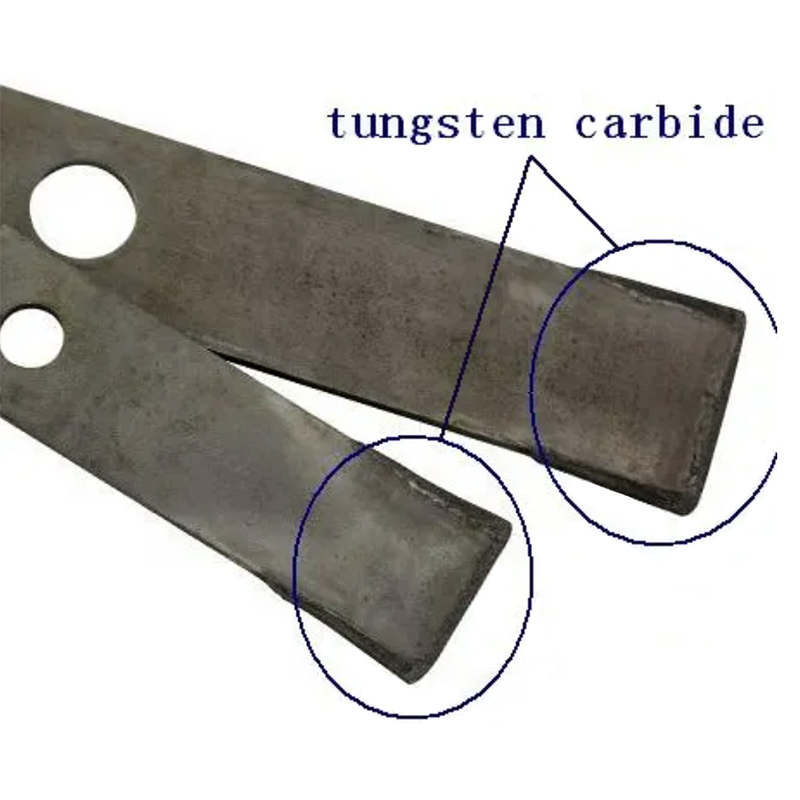

1. Lithako tsa hamore li matlafatsoa ke boima bo phahameng, li-welding tse phahameng tsa tungsten carbide overlay welding le spray welding, e hlahisang ts'ebetso e ntle le e phahameng.

2. Li-hamore tsa Tungsten carbide hamore li hanyetsana haholo le ho bola, li etsa hore e be tse loketseng bakeng sa ho pepesehela tikoloho e mongobo kapa ea lik'hemik'hale.

3. Tungsten carbide ke e 'ngoe ea lisebelisoa tse thata ka ho fetisisa tse fumanehang, e leng se bolelang hore li-hamore tsa tungsten carbide li hanyetsa haholo ho apara le ho taboha' me li ka mamella tšebeliso e boima ntle le ho robeha kapa ho senyeha.

4. Lihamore tsa Tungsten carbide li ka sebelisoa ka li-crusher tse fapaneng tsa mohlahare, li-crusher tsa joang, li-crusher tsa patsi, li-crusher tsa sawdust, li-dryer, mechine ea mashala, joalo-joalo.

Li-Hammer Blade tse fapaneng

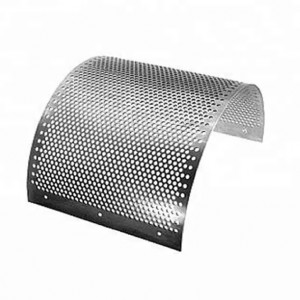

Likarolo tse ling tsa Spare